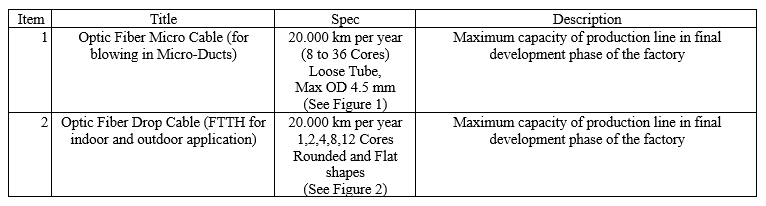

Optic Fiber Cable Production Machine

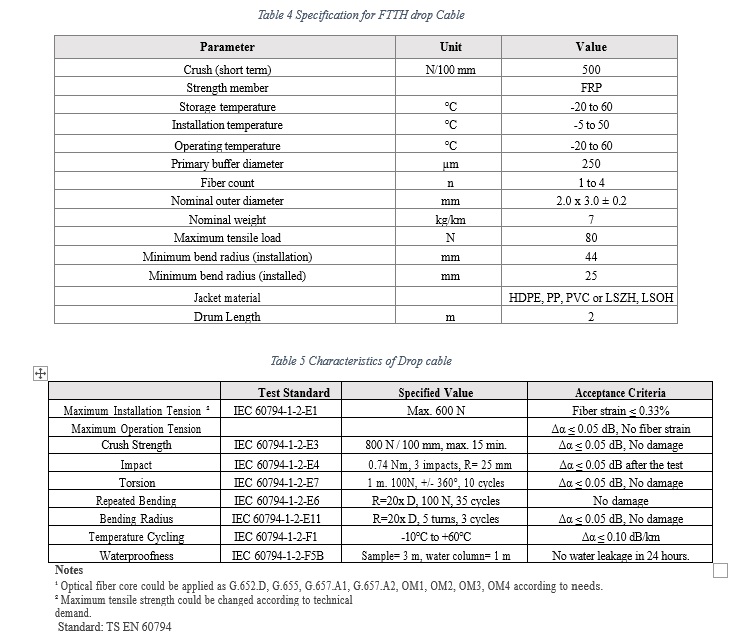

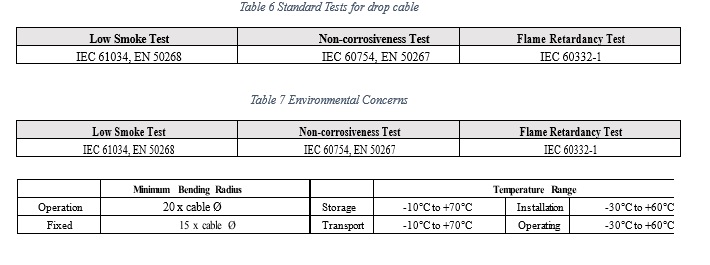

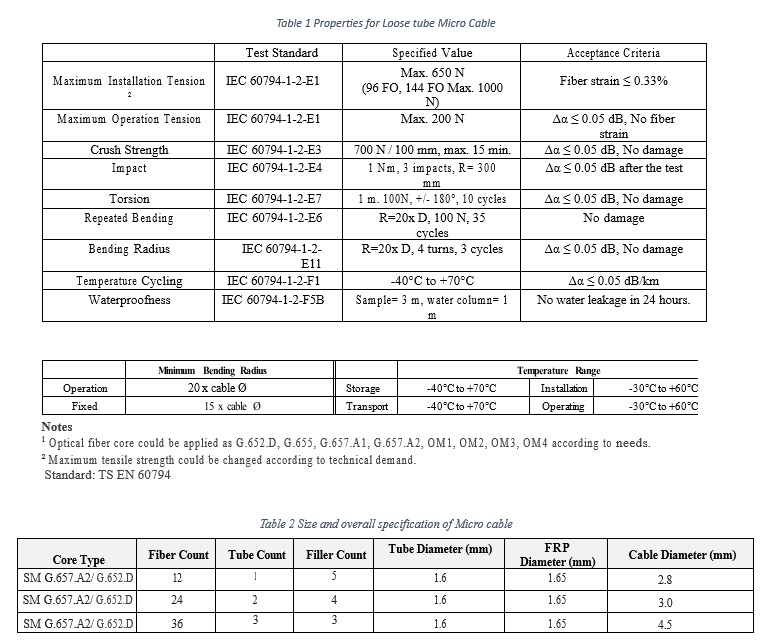

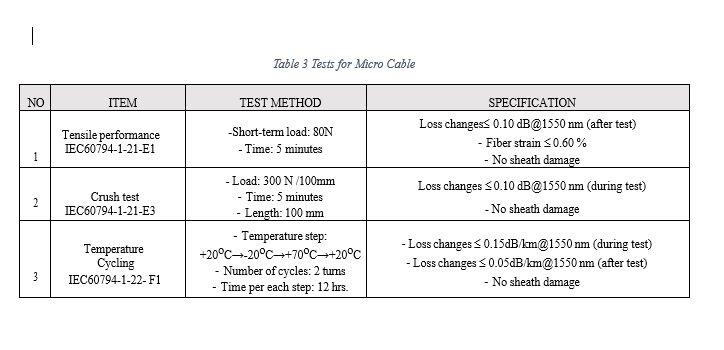

The specification and requirements are listed in the table below:

Notes:

- The important point in designation of the machine is its energy consumption and production rate (efficiency).

- All standards for Optic Fiber Cable must be passed by final products.

- Regarding our production target it is needed to have an efficient line with at least 250 m/min production capacity.

- The Machines must can make different product shapes regarding FTTH needs and regulations.

- Maximum length of each proposed production lines must not exceed 55 meters.

- Easy and fast installation due to its small diameter and light construction.

Suitable for pushing, blowing method.

- Problem-free use in power lines due to its non- metallic

- In network systems, MAN, WAN, LAN

- As a backbone cable in FTTX

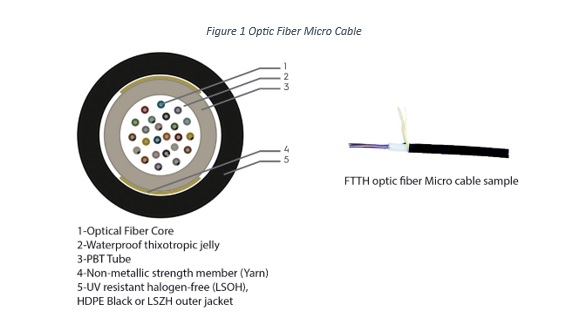

- – Optical fiber core

- – Waterproof thixotropic jelly

- – PBT Tube

- – Non-metallic central strength member (FRP)

- – Water-swellable yarn

- – Ripcord

- – UV resistant polyethylene (HDPE) black outer jacket, LSZH or LSOH

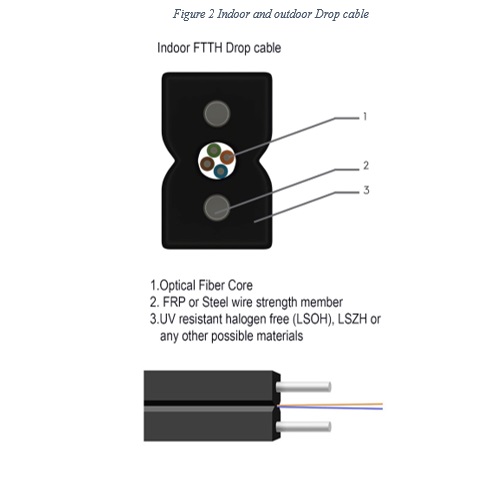

Optical Drop Cable:

Drop Cable for FTTH network

Applications:

- Suitable for FTTX networks and access networks.

- Can be used to connect subscriber units to building entry cabinets.

Features:

- Capable of accommodating 1 to 8 fibers.

- Approximate dimensions of 3×2 millimeters.

- Equipped with two non-metallic FRP elements to protect optical fibers1.

- Direct connector installation possible.

- Has a desirable bending radius and high tensile strength.

- Features LSZH coating to prevent flame spread and the release of toxic gases after ignition.

- Capability of production with PVC and polyethylene PE coatings.

- This cable is produced in two variants: Indoor (with white or yellow coating) and Outdoor (with black coating).